Pilot Operated Pressure and Vacuum Relief Valves

Pilot-Operated Relief Valves emply a sensing 'pilot' line to narrow the gap between operating and relief pressures to increase efficiency and reduce evapaoration losses.

![]()

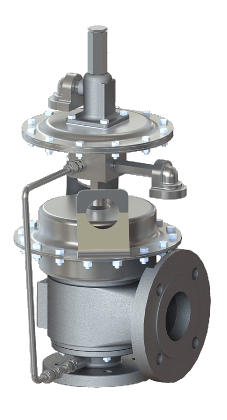

Model 1400A

Model 1400A

Groth Pilot Operated Relief Valve with Vacuum Breaker

The Groth Series 1300A is used when vacuum relief is the only requirement. Intake relief necessary under working conditions is achieved by a spring or weight loaded pallet. This feature reduces the possibility of tank damage due to an excessive vacuum condition. The 1300A Series helps to provide increased fire protection and safety. Valve size must be selected to perform required vacuum relief under operating and thermal conditions.

- Ease of precision settings

- Only the pilot needs to be set

- Lower profile and weight than spring operated models for high settings

- Remote pilot sensing option allows the pilot to sense the true system pressure

- Remote or manual blowdown available

- Main valve remains tight to set pressure

- Full open at 10% overpressure

- Modulating action conserves product

- Soft seating creates tight seal to conserve product and minimize valve wear

- Top entry allows valve to be services without removal from mounting

![]()

Model 1420

Model 1420

Groth Pilot Operated Relief Valve with Vacuum Breaker

The Groth 1400 Series Pilot-Operated Relief Valves are used to replace weight-loaded or spring loaded valves in many applications to increase efficiency and reduce evaporation losses. Several advantages are obtained over the traditional valves. For example, the process pressures may be closer to the set pressure than would be considered prudent and safe with the traditional valve. Additionally, greater conservation is obtained due to minimum product loss which in turn provides increased profits.

- Ease of precision settings

- Only the pilot needs to be set

- Lower profile and weight than spring operated models for high settings

- Remote pilot sensing option allows the pilot to sense the true system pressure

- Remote or manual blowdown available

- Main valve remains tight to set pressure

- Full open at 10% overpressure

- Modulating action conserves product

- Soft seating creates tight seal to conserve product and minimize valve wear

- Top entry allows valve to be services without removal from mounting

![]()

Model 1430

Model 1430

Groth Pilot Operated Relief Valve

The Groth 1400 Series Pilot-Operated Relief Valves are used to replace weight-loaded or spring loaded valves in many applications to increase efficiency and reduce evaporation losses. Several advantages are obtained over the traditional valves. For example, the process pressures may be closer to the set pressure than would be considered prudent and safe with the traditional valve. Additionally, greater conservation is obtained due to minimum product loss which in turn provides increased profits.

The 1430 is similar to the 1400 but without a vacuum breaker.

- Ease of precision settings

- Only the pilot needs to be set

- Lower profile and weight than spring operated models for high settings

- Remote pilot sensing option allows the pilot to sense the true system pressure

- Remote or manual blowdown available

- Main valve remains tight to set pressure

- Full open at 10% overpressure

- Modulating action conserves product

- Soft seating creates tight seal to conserve product and minimize valve wear

- Top entry allows valve to be services without removal from mounting

![]()

Model 1460

Model 1460

Groth Pilot Operated Relief Valve

The Groth 1400 Series Pilot-Operated Relief Valves are used to replace weight-loaded or spring loaded valves in many applications to increase efficiency and reduce evaporation losses. Several advantages are obtained over the traditional valves. For example, the process pressures may be closer to the set pressure than would be considered prudent and safe with the traditional valve. Additionally, greater conservation is obtained due to minimum product loss which in turn provides increased profits.

The 1460 is similar to the 1420 but without a vacuum breaker.

- Ease of precision settings

- Only the pilot needs to be set

- Lower profile and weight than spring operated models for high settings

- Remote pilot sensing option allows the pilot to sense the true system pressure

- Remote or manual blowdown available

- Main valve remains tight to set pressure

- Full open at 10% overpressure

- Modulating action conserves product

- Soft seating creates tight seal to conserve product and minimize valve wear

- Top entry allows valve to be services without removal from mounting

![]()

Model 1660A

Model 1660A

Groth Pilot Operated Relief Valve

The Groth 1600 Series valves provide safe, dependable, and accurate low pressure and/or vacuum protection. Seals in accordance with API 2000 requirements for Pilot Operated Relief Valves. This design prevents fugitive emissions and conserves stored product. Rated flow at 10% overpressure provides the ability to operate closer to the tank MAWP, increasing the operating range of the process. This reduces the need for a large overpressure and saves product, which translates into profit. Flexibility in terms of film or o-ring seat and snap or modulating action allows product customization to specific application requirements. The Model 1662A incorporates a vacuum breaker.

- Ease of precision settings

- Main valve remains tight to set pressure

- Full open at 10% overpressure

- Modulating action conserves product since valve opening is proportional to overpressure

- Noise is reduced since the valve only opens fully when required

- Soft seats seal tight to conserve product and minimize valve wear which improves reliability